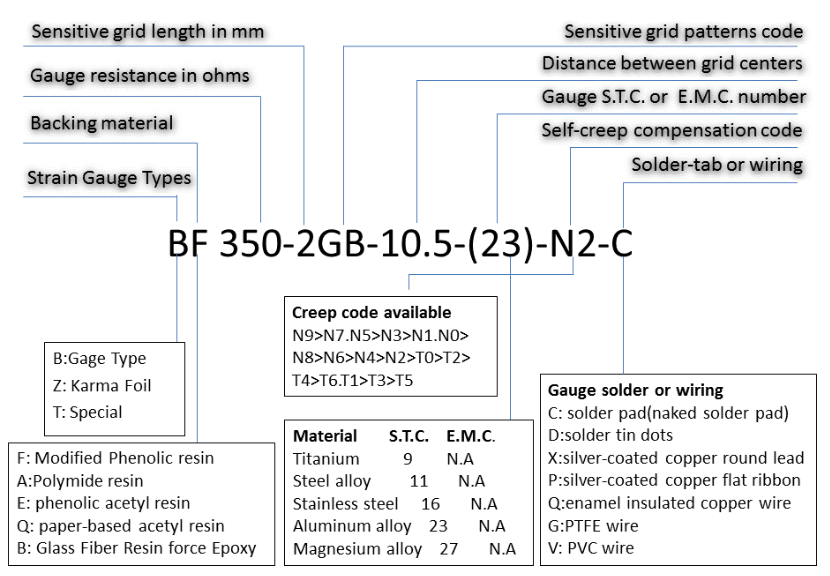

Ordering code:

|

BF series |

BA series |

ZF series |

|

modified phenolic resin backing, constantan alloy, encapsulated gauges with temperature compensation and creep compensation; high accuracy, good stability , for manufacturing precision transducers (0.02%FS)

|

Polyamide resin n constantan alloy, encapsulated gauges with temperature compensation, high elongation, wider operating temperature range, suitable for stress analysis under 150 ℃ and build in 0 . 0 5 % F S accuracy transducers. |

modified phenolic resin backing karma alloy encapsulated gauges with temperature compensation and creep compensation(or modulus compensation) high accuracy good stability, high resistance, small power loss for manufacturing 0.02%FS accuracy transducers. |

|

specification |

BF series |

BA series |

ZF series |

|

nominal resistance(Ω) |

3,506,501,000 |

3,506,501,000 |

3,506,501,000 |

|

tolerance of resistance |

<±0.1% |

<±0.1% |

<±0.1% |

|

gauge factor |

2.00~2.20 |

1.86~2.20 |

1.86~2.40 |

|

gauge factor resistance |

<±1% |

<±1% |

<±1% |

|

strain limit |

2.00% |

2.00% |

2.00% |

|

fatigue life |

>107 |

>107 |

>108 |

|

effective modulus compensation |

not available |

not available |

aluminum(23) |

|

metal foil |

constantan alloy |

karma alloy |

constantan alloy |

|

creep compensation |

available |

available |

available |

|

working temperature range |

-30~+80℃ |

-30~+150℃ |

-30~+80℃ |

|

temperature compensation |

titanium(9), mild steel(11), stainless steel(16), aluminium(23), magnesium(27), plexiglass(65) |

||

|

curing temperature |

135℃(curing process) 165℃(post curing process) |

||

|

MODEL |

GRID DIM |

BACKING DIM |

CREEP |

|||

|

L (mm) |

W (mm) |

L (mm) |

W (mm) |

|||

|

BF(BA)350-2FB(**) |

2.0 |

2.8 |

6.4 |

7.6 |

|

|

|

BF(BA)350-3FB(**) |

3.2 |

2.8 |

7.4 |

7.4 |

N0,N2,T0 |

|

|

BF(BA)350-3FB(**) |

2.9 |

2.6 |

7.4 |

7.2 |

|

|

|

BF(BA)350-4FB(**) |

4.0 |

2.4 |

8.2 |

6.8 |

||

|

BF(BA)350-6FB(**) |

5.9 |

2.8 |

9.8 |

7.3 |

||